More Resources

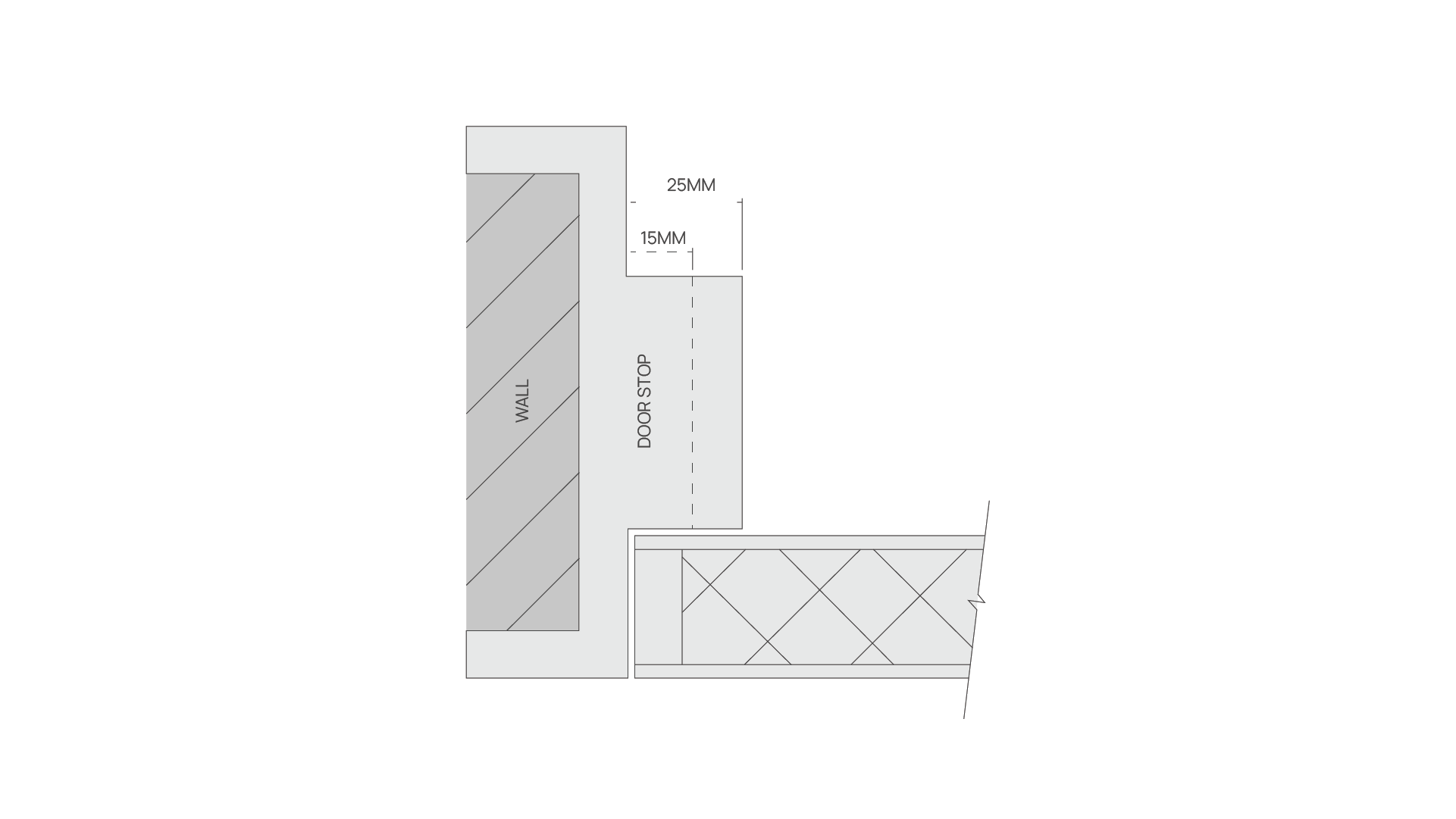

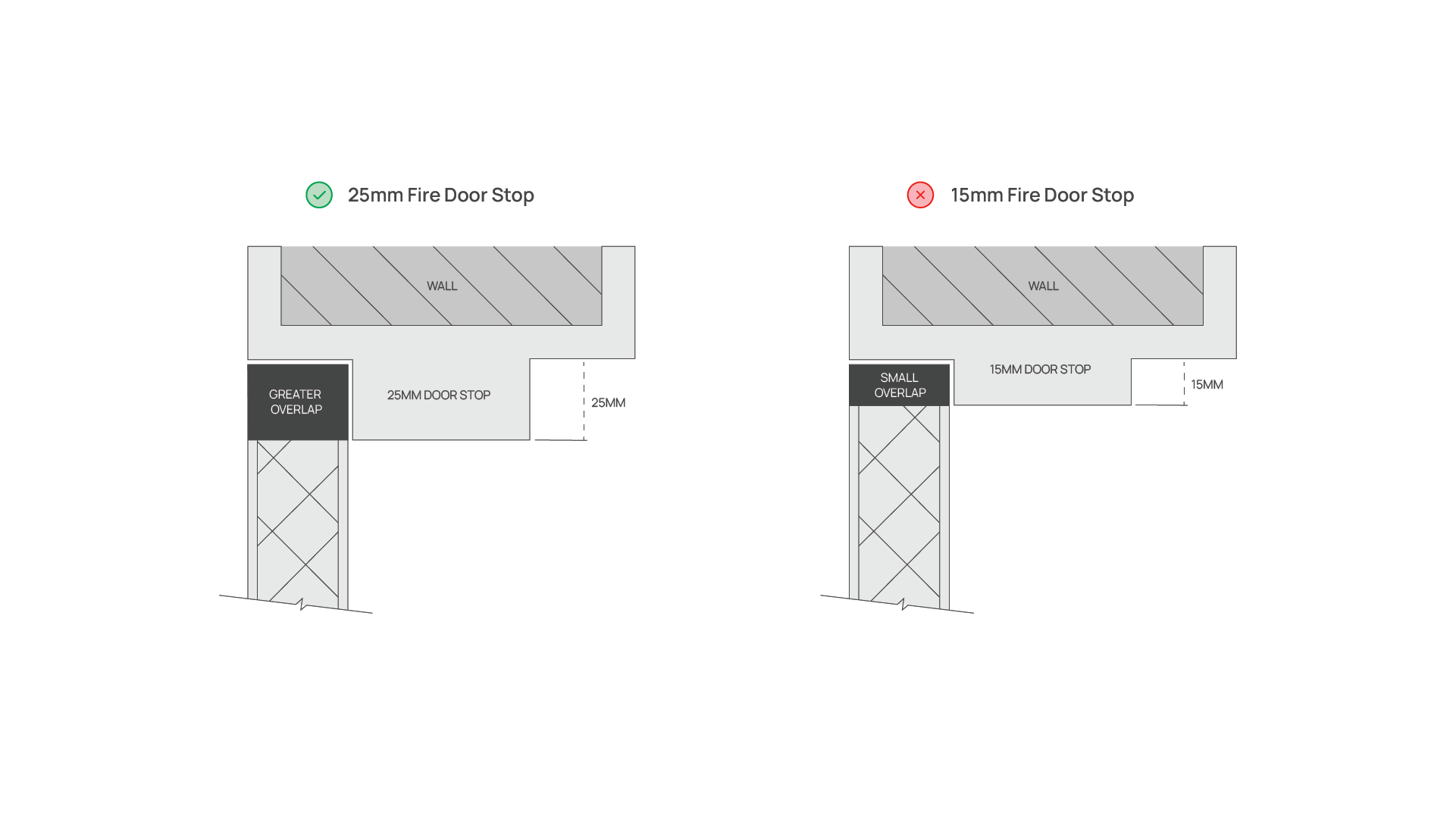

Fire Safety Doors

Outline the ferocity of smoke in a building that is unprotected with appropriate smoke separation.

Extinguisher Spacing

Spacing in Apartments

Outlining how the severities of standards are determined by Australian regulatory body.

Defects

New Building Defects

Outlining the process of how properties receive an occupancy permit without a Compliance Certificate